Characteristics

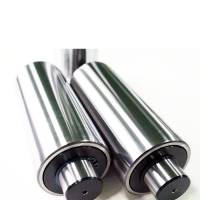

Back-up rollers for metal flattening machines are made in two different executions:

1.full complement of cylindrical rollers

2.with roller cages in mould steel or bronze.

Back-up roller is very impotant in the flattening processes: choose the high quality of MONTON bearings means to improve the machining tolerances and to significantly reduce the cost.

Back up rollers for steel industry, mainly used in the flattening and straightening lines of steel, stainless steel, aluminium sheets.

In addition, the range also includes double back-up rollers with pin, back-up rollers with tapered rollers, simple support rollers.

The full complement execution allows the bearing to reach a high load capacity both dynamic and static.

Back-up rollers with pivot for metal flattening machines have the following characteristics:

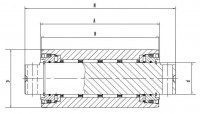

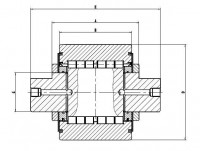

The outer ring is supplied in Gcr15 core hardened steel that can reach hardness 60-2 HRC.

Once seen the condition of coupling with working cylinders, the degree of hardness can be reduced to 53/58 on request.

The profile of the outer ring is usually cambered in order to optimize the distribution of the applied load.

The pivot is made in two different steel types, according to dimension and shape:

1) core hardened steel Gcr15/100 CrMo7;

2) case hardened steel 18 NiCrMo5.

In both cases the degree of hardness is 60-HRC.

The bearings have a grease lubrication system and are supplied already pre-lubricated. The lubrication system foresees both the entrance and the exit of grease. They can be supplied also in Long-life execution.

The sealing system is very efficient, it does not allow outer agents (such as, dust, mill scale, humidity) to enter the back-up roll; at the same time, it prevents the leakage of grease.

Precision class P0; on request the rollers can be manufactured with precision class P5 (DIN 620) and selected in groups.

Back-up roller advantages:

1) Excellent and high quality control

2) Prompt delivery

3) Competitive price

4) OEM service

5) Customers' drawing or samples accepted

List of customized parts from customer:

| Designation | d | D | H | A | B | Cw | Cow | RPM |

| BUR47145A | 20 | 47 | 145 | 116.6 | 115 | 87 | 105 | 5600 |

| BUR47145B | 20 | 47 | 145 | 115.6 | 115 | 87 | 105 | 5600 |

| BUR74192A | 40 | 74 | 192 | 151.8 | 150 | 155 | 205 | 4000 |

| BUR74192B | 40 | 74 | 192 | 151.8 | 150 | 155 | 205 | 4000 |

| BURT112230A | 40 | 112 | 230 | 170 | 150 | 403 | 759 | 800 |

| BURT68230B | 28 | 68 | 230 | 200 | 85 | 254 | 459 | 1200 |

| select | Inquiry | Designation | d (mm) | D (mm) | L (mm) | B (mm) | E (mm) | h (mm) | Rollers Rows | Cw (KW) | Cow (KW) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MT 100X45X246 | 45 | 100 | 246 | 200 | 201,4 | - | 4 | 280,8 | 415,8 | ||

| MT 134X55X146 | 55 | 134 | 146 | 83 | 85 | 50 | 2 | 227,9 | 315 | ||

| BUR47145A | 20 | 47 | 145 | 116.6 | 115 | 87 | |||||

| BUR47145B | 20 | 47 | 145 | 115.6 | 115 | 87 | |||||

| BUR74192A | 40 | 74 | 192 | 151.8 | 150 | 155 | |||||

| BUR74192B | 40 | 74 | 192 | 151.8 | 150 | 155 | |||||

| BURT112230A | 40 | 112 | 230 | 170 | 150 | 403 | |||||

| BURT68230B | 28 | 68 | 230 | 200 | 85 | 254 | |||||