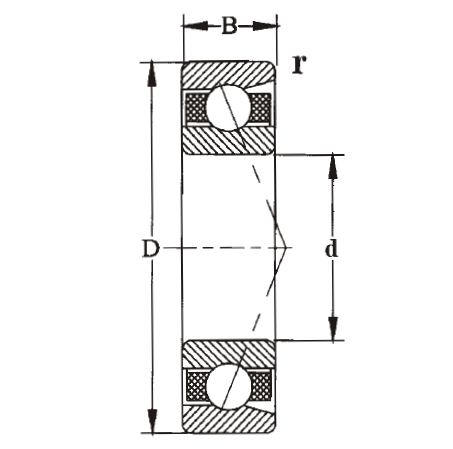

MONTON B72XX robust Series angular contact ball bearings size from10mm-400 mm. B72 series bearings have a large cross-section height and suitable for heavy-load, low-speed application. MONTON provides bearings with contact angles of 15°, 18°, 25°, 30° and 40°. The contact angle increases, the axial load capacity increases, and the speed will decreases. At the same time, MONTON can also provide high-load and high-speed design. The rolling elements include steel balls and hybrid ceramic balls for customers to choose from. There are open and sealed bearings to provide better support for customers.

MONTON B72XX robust series angular contact ball bearings are mainly suitable for heavy-load, low-speed applications. Our company provides different products and arrangment for each customer according to the specific working conditions of the customer. MONTON can provide customers with different precisions of P5, P4, and P2. The additional advantage of ceramic ball bearings in speed enables the B72 robust series to also run at high speed. Therefore, it will have higher rigidity, higher speed, lower friction, lower loss, longer bearing lubrication service life, higher precision, and reduce the outer ring rolling contact stress at high speed. The B72XX series angular contact ball bearings with integrated seals installed on both ends can extend the service life and maintenance cycle of the bearings.

MONTON's different bearing variant designs include:

1. Single installation U (universal) or assembled in group ad D (Double) T (Triple) Q (Quater), etc.

2. Universal bearings or universal bearing sets

3. Bearings using steel balls or hybrid ceramic ball bearings

4. Open bearings or bearings with seals on both sides

5. Bearings directly lubricated through the circumferential lubrication grooves and radial lubrication holes on the outer ring of the bearing

6. Preload is divided into three types: light L, medium M, and heavy H

Main applications include:

1. Machine tool spindle Live center

2. Lathe (spindle, tailstock)

3. Grinding machine

4. Boring machine

5. Parallel machine tool

6. Engine test dynamometer

7. High-speed turbocharger

8. Photovoltaic cutting machine

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and application. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service department directly.